Webinar on Emerging Challenges and New Technologies in Modern Manufacturing Industries Conducted

An online presentation about “Emerging Challenges and New Technologies in Modern Manufacturing Industries” was delivered by Mr. K. K. Natarajan, a lecturer of the Mechanical Section on 2nd February 2021. The webinar, which took place between 12:15PM and 1:15PM was organized by the Research Committee of the Engineering Department.

Below is an excerpt from the presentation of Mr. Natarajan.

The manufacturing sector has made enormous progress. Manufacturing and industrialization processes have now entered their fourth generation of the industrial revolution through numerous innovations and repeated experiments over the years. There have been a variety of developments and reforms during this time. Manufacturers face demand as never before in today's rapidly evolving global economy, so they must have excellence in order to thrive.

The related developments (such as artificial intelligence, cyber-physical networks, Big Data analytics, Enhanced and Virtual Reality, IoT, robotic technology, etc.) have to be better developed in the industrial sector for the efficient application of intelligent development technology.

The first part of modern technologies in mechanical engineering is the Industrial Revolution. Industrial Revolution 4.0 is the age of the intelligent industries, in which computer and electrical technology are interconnected with mechanical technologies.

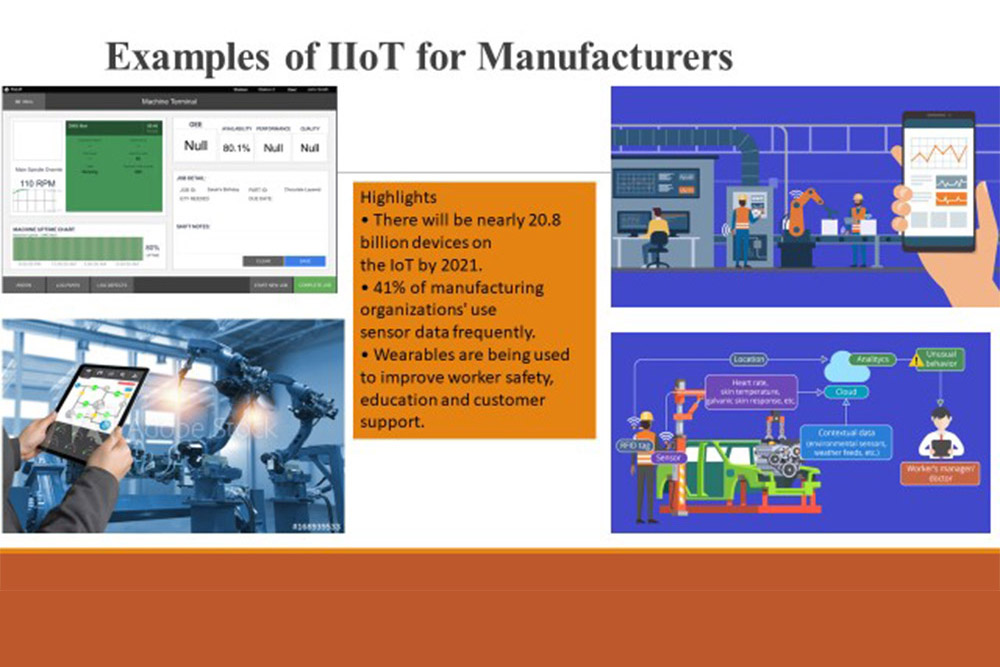

Interestingly, the Internet of things (IoT) takes into account Industrial Revolution 4.0, and in Mechanical Engineering, IoT is a big component of emerging technologies. Life has become simple with this technology as the time required to do a particular work has been decreased. The remotely controlled CNC machines through IoT greatly reduces the risk of occupational hazards since human contact is not required.

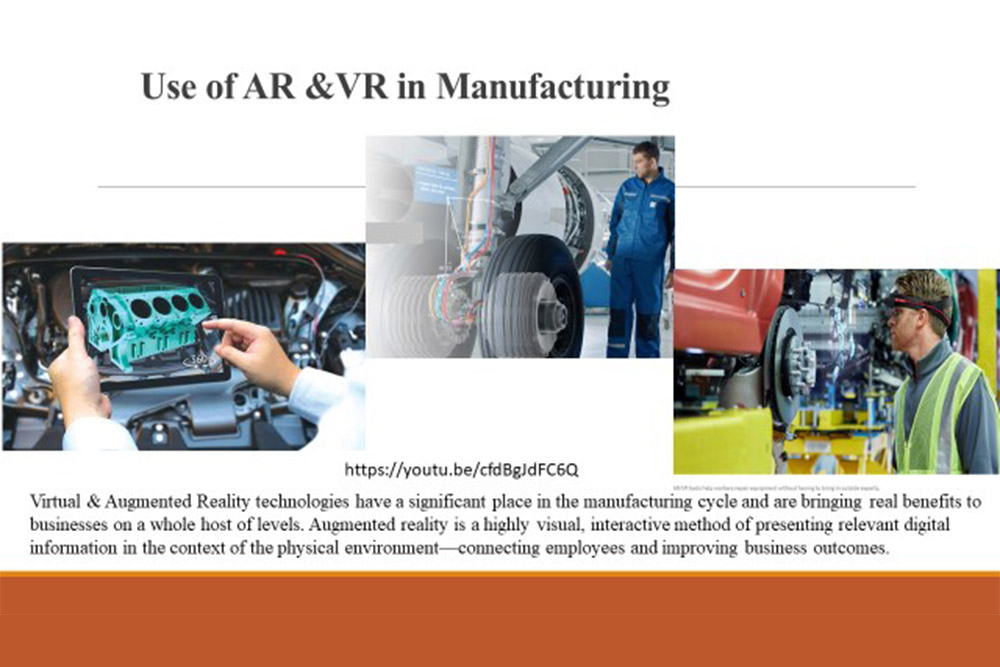

On the other hand, VR and AR give product design departments unique opportunities to shape and validate their designs correctly prior to any actual shape.

Meanwhile, cobots prove AI is not made to take on human workers and automation. They are designed to collaborate with workers to produce items quicker and to improve current practices to allow for the performance of jobs with greater precision.

The key drivers of the industrial revolution today are mechanical engineering technology. This leads to automation without a human-specific interface, increased productivity, and a high degree of efficiency. It allows people to have a greater precision in doing their jobs.